Complexity in commercial HVAC and plumbing takes many forms. This is where we thrive:

Conversely, you might find more suitable HVAC and plumbing providers for office parks, apartment complexes or facilities with simple designs.

We then gather internally to determine the best approach to your project, which we’ll detail in a proposal.

What sets us apart here is foresight. Experience has taught us how to anticipate gaps in scope and items not reflected in drawings or specification docs. This is how we work – to help you anticipate issues and minimize “surprises” during project construction.

That “best approach” may not be a single answer; it might include options. But it always reflects our deep experience as well as an effort to add efficiency and value, without compromising any of your project requirements.

The point is: We begin to explore and solve even before the project is awarded to us. If you choose to work with us, we move on to more detailed planning in the preconstruction phase.

When pricing our work, we use model-based estimating. This adds precision and transparency, so you’ll get a detailed estimate, down to the individual fitting and associated labor hours.

Our priority is to work with you closely – to help you anticipate issues and minimize “surprises” during project construction.

This includes:

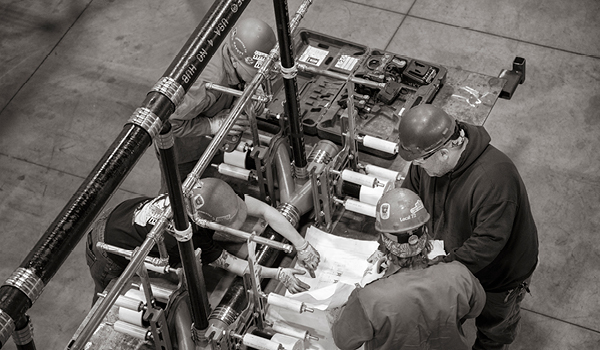

During pre-construction we look for ways to deliver a project more efficiently and safely by maximizing pre-fabrication. Our more than 200,000 square feet of fabrication space enables us to achieve so much before working on the job site. (More on that below; or scroll above to watch a video.)

When changes are made in the field, we’ll instantly incorporate them into all drawings and models, to help plans stay accurate all the way to the end. That’s the advantage of using advanced technology.

The footprint of our Winship at Midtown project, a 17-story specialized cancer care facility in Atlanta. Emory University hired us for mechanical HVAC construction. B&K also handles nearly all routine plumbing and HVAC work for Emory University Hospital’s main and Midtown campuses.

In fabrication, we’re building mechanical components and systems in a tightly controlled environment. Each project is fabricated into a work package, and each work package is tracked digitally with proprietary software.

That means fewer people are needed on the job site – which promotes safety, cost savings, and efficiency.

Fabrication helps ensure a better product. Every joint, every component, is inspected before it ever arrives at a job site. It also means a lot less material is wasted, and that helps save money.

Your Batchelor & Kimball field team is built with union members who have deep experience and training in their craft.

Most have been with us a long time. Our younger and newer professionals have been through a rigorous screening process, which includes assessments for strong cognitive reasoning and collaborative, professional behavior. They’re also trained through a state-of-the-art apprenticeship school and get supervised, hands-on experience in the field.

Typically, we first hire talented people as interns, co-ops, apprentices and contract professionals. This contingency allows us and the employee to determine a “good fit” for a longer tenure. To uphold our high standards, we aim to promote from within the ranks.

To assure consistency, we work only with a select group of experienced subcontractors – craftsmen (and women) we’ve worked with for decades. And we bring in licensed, independent professionals to inspect the work of our team before it’s delivered.

In our fabrication shops, we handle miles of piping – as wide as 6 feet in diameter, and as small as ¼ of an inch.

Does it function as promised? Will it serve your facility well in the long term?

In the end, you need certainty – and that’s what our commissioning team provides.

If commissioning starts just as construction is wrapping up, that’s too late. B&K’s commissioning technicians are involved in the design and preconstruction stages, helping to develop the plan and shaping the specifications.

They’re also engaged throughout construction – tracking the commissioning plan, helping to navigate complexity and verifying that specifications are met.

Ultimately, they’ll monitor the startup process of all systems. And once our construction work is completed, if required, B&K brings in a third-party inspector to conduct a final assessment.

The final transition to the facility owner needs to be seamless. We provide:

Many of our facility clients choose to continue working with Batchelor & Kimball to repair and maintain their facilities and system controls.

See what we can do for your facility >